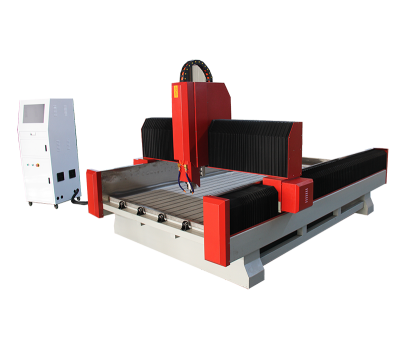

Stone Carving Series CNC Router

Stone Series CNC Router

AlphaCNC stone series CNC router is designed to deal with stone cutting or engraving work, this kind machine adopts strengthen steel structure, steady and rigid. Top brand linear guide and sliding tracks make the machine working stable and endurable. Its spindle and motors have a good power, which is guarantee of cutting/engraving capability and working efficiency.

CNC for stone is compatible with different softwares and its double cooling system helps useful time extension.

Welcome to contact us for more information.

Uses & Applications

Stone Series has unlimited uses and applications, including:

- Tombstone

- Counter Top

- Sign making

- Engineering

- R&D/Job shops

- Musical instrument manufacturing

- Medium duty to high production

- Solid Surface work

- Non-Ferrous material processing

Materials Cut

Stone Series can accurately cut virtually any hard material including:

- Stone

- Marble

- Granite

- Blue Stone

- Sand Stone

- Quartz

- Foam

- Aluminum

- and More

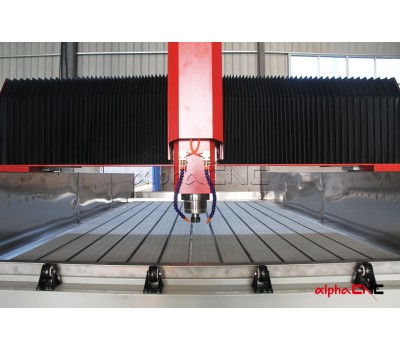

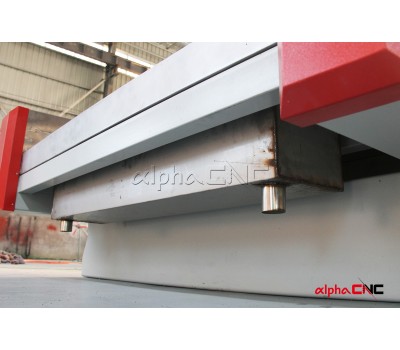

- Welded steel construction with Stress Relieved Technology

- Steel Tube Gantry (Most Rigid in Class)

- Heavy duty motors (Most Industrial in class)

- Auto Tool Zero Sensor

- 4.5kw Liquid-Coolant Spindle, Water-resistant

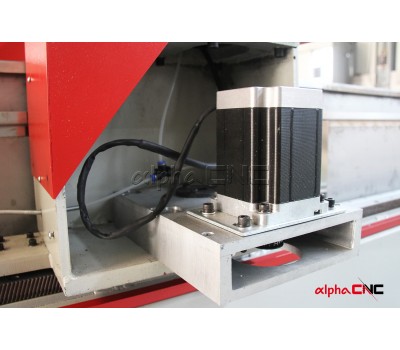

- Nema 34 Stepper Motor

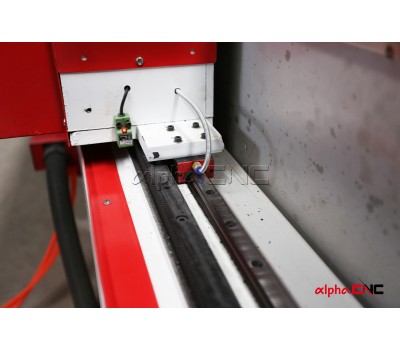

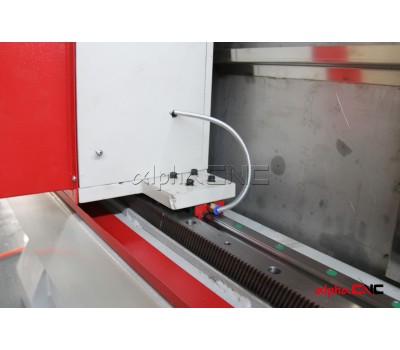

- Helical Rack & Pinion Gear On XY Axis, Ball Screw On Z Axis

- Hiwin Linear Rail

- Mach 3 Ethernet Controller

- Foot Leveling Pad

- Staninless Steel Water Tray, Cutter Coolant Water Recycling

- No assembly required – No Bolt Together Designs

- Custom options available to meet your exact needs

- Free lifetime tech support

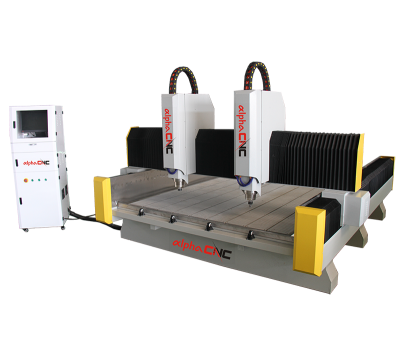

| ASC-1325 | ASC-1530 | ASC-1625-2 | |

|---|---|---|---|

| Footprint | 2250*3300*1900mm | 2450*3800*1900mm | 2950*4800*1900mm |

| Cut Area | 1300*2500*300mm | 1500*3000*300mm | 1600*2500*300mm |

| Z Clearance | 300mm standard | 300mm standard | 300mm standard |

| Rapid Speed | 18 m/min | 18 m/min | 18 m/min |

| Repeatability | ±0.05mm | ±0.05mm | ±0.05mm |

| Drive Motors | Leadshine Nema 34 Stepper Motor System | Leadshine Nema 34 Stepper Motor System | Leadshine Nema 34 Stepper Motor System |

| Drive System | Ball Screw Z axis, Rack And Pinion Gear on X & Dual Y Axis | Ball Screw Z axis, Rack And Pinion Gear on X & Dual Y Axis | Ball Screw Z axis, Rack And Pinion Gear on X & Dual Y Axis |

| Spindle | 4.5kw Liquid-Coolant Spindle | 4.5kw Liquid-Coolant Spindle | TWO 4.5kw Liquid-Coolant Spindle |

| Control | Mach 3 Ethernet Controller | Mach 3 Ethernet Controller | Mach 3 Ethernet Controller |

Standard Available options

Available attachments for Alpha CNC router models. Please note that some options may not be available on all models or with other options. Some options may result in limiting the cutting/working areas. Contact us for more details

- Vacuum Cup For Holding Marble Slab

- 5.5kw or higher rated Spindle

- Hybrid Servo Motor

- Delta Servo Motor

- Yaskawa Servo Motor

So, what software is involved in CNC? There are primarily three parts:

- Your CAD (Computer Aided Design) software is where you design your parts to be routed, lathed, milled, or cut.

- CAM (Computer Aided Manufacturing) software converts your CAD drawings into G-code, which is the programming language that the CNC control software understands.

- The CNC control software (which is the controller of the machine)then reads the G-code and turns it into motion to drive your machine.

Software We Suggest (CAD/CAM all in one)

- Vectric Aspire

- Autodesk Fusion 360

- Mozaik – Specialized in cabinet & furniture

CAD Software

- Google Sketchup – FREE

- Blender – FREE

- Caligari TrueSpace – FREE

- Wings 3D – FREE

- Moi3D

- Corel CAD

- ArtCam

- SolidWorks

- RhinoCAD

- SolidEdge

- AutoCAD

- TurboCAD

- Alibre

CAM Software