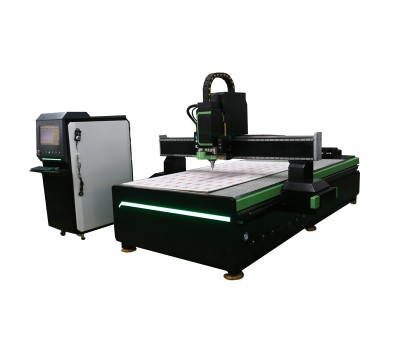

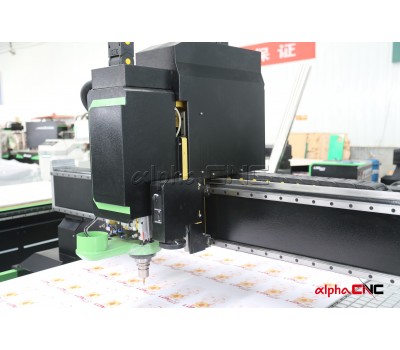

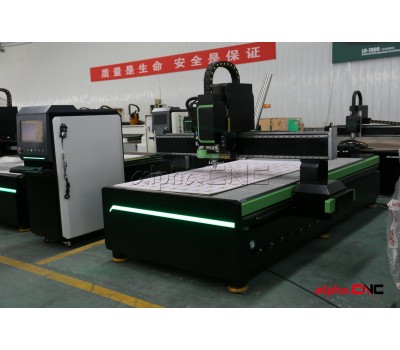

Spindle+Oscillating Knife+CCD Graphics And Print Finishing Sign Making CNC Router

Furture Of CNC: Diversification.

Digital finishers are being asked to do more including routing aluminum and acrylic and cutting/trimming paper, vinyl, foam board, coroplast, styrene and rubber. As a result, we challenged our engineering team to develop a CNC router that meets the traditional demands of the digital finishing industry while delivering overwhelming power to take on broader projects.

WHAT MAKES IT UNIQUE?

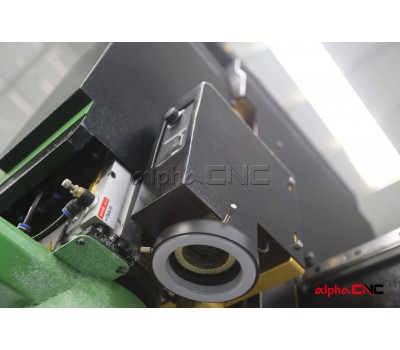

Processing a wide range of materials requires more than one cutting head. The ARK series can combine two or three different cutting technologies to provide maximum versatility by offering a choice of routing spindle and one or two knives which can be either tangential, oscillating, or a combination of both.

Hybrid head on narrow carriage for small footprint

High-power router for fast processing of tough materials

Tangential and oscillating knife tools for all flexible and semi-rigid materials

High gantry clearance allows processing of materials up to 5″ thickness

Combine the machine with Alpha Vision System and you have a truly flexible machine for all applications.

WHO IS IT FOR?

Alpha Router-Knife (ARK) series is an innovative hybrid CNC production system combining heavy-duty routing with fast knife cutting for processing the broadest range of materials in all print finishing, sign making, foam and graphics applications. Popular applications include:

- Graphics and Print Finishing – Cut-to-print using multiple tools for all materials

- Sign making – All types of 2D and 3D signs in woods, metals and plastics

- Foam Packaging – 2D and 3D processing with router and knife tools

- Point of Purchase – Display stands, fixtures and fittings

Materials Cut

Using our knife cutting systems you can process a wide range of materials including, but not limited to.

- Carpet

- Felt

- Foam

- Closed Cell Foam

- Composites

- Gasket Materials

- Fabric

- Snowboard

- and More

- Welded steel construction with Stress Relieved Technology

- Steel Tube Gantry (Most Rigid in Class)

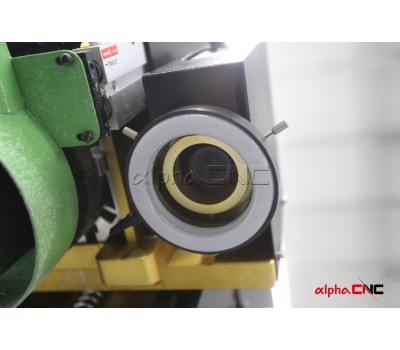

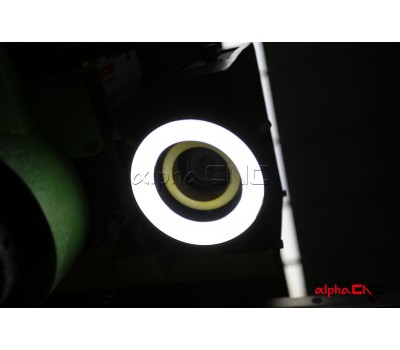

- High frequency 3.2kw 6,000-24,000rmp spindle

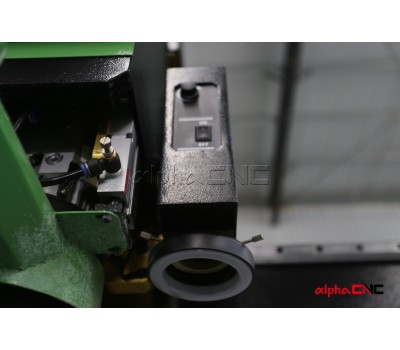

- Oscillating knife( Tangential Knife, Kiss cut, Crease for option)

- Hybrid Vacuum and Aluminum T-slot table

- Mach 3 Ethernet Controller and TL Controller(Syntec for option)

- Servo motors

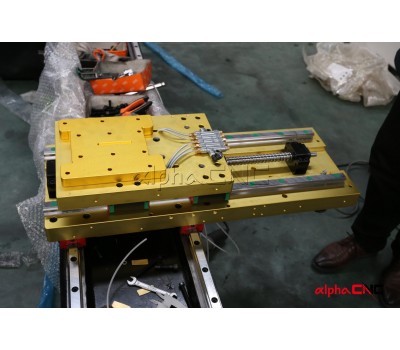

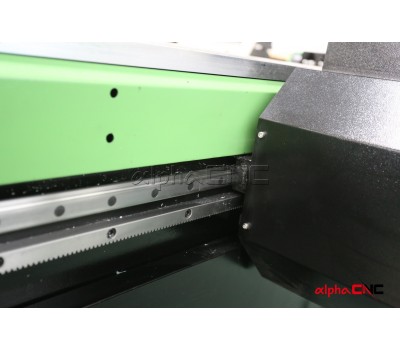

- Hiwin 20mm Lienar Rail

- Helical Rack & Pinion Gear On XY Axis, Ball Screw On Z Axis

- Z axis high precision ballscrew

- Tool Calibration

- Vision System for option

- Free lifetime tech support

| ARF-1325 | ARF-1530 | |

|---|---|---|

| Cut Area | 1300*2500*150mm | 1500*3000*150mm |

| Rapid Speed | 60 m/min | 60 m/min |

| Repeatability | ±0.05mm | ±0.05mm |

| Drive Motors | Delta Servo motor and driver | Delta Servo motor and driver |

| Working Voltage | AC380V/3PH/50Hz(option:220V) | AC380V/3PH/50Hz(option:220V) |

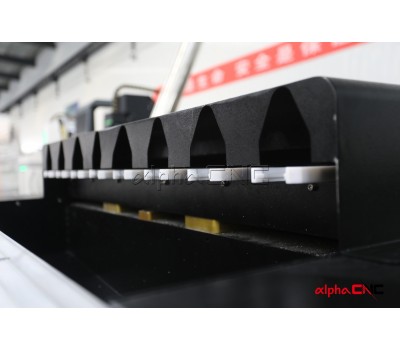

| Spindle Power | 9kw ATC air cooling spindle | 9kw ATC air cooling spindle |

| Knife | Oscillating Knife | Oscillating Knife |

| Control | Nc-studio(Weihong) V10 | Nc-studio(Weihong) V10 |

| Command Language | G Code | G Code |

| Interface | USB | USB |

| Software capabilities | Option: Vectric Aspire, Type3, Ucancam, Artcam, Solidworks, etc. | Option: Vectric Aspire, Type3, Ucancam, Artcam, Solidworks, etc. |

Standard Available options

Available attachments for Alpha CNC router models. Please note that some options may not be available on all models or with other options. Some options may result in limiting the cutting/working areas. Contact us for more details

- Hybrid T-Slot/Vacuum Table Top (Included Dry Rotary Vane Vacuum Pump)

- Rotary Axis

- Dust Collector Options

So, what software is involved in CNC? There are primarily three parts:

- Your CAD (Computer Aided Design) software is where you design your parts to be routed, lathed, milled, or cut.

- CAM (Computer Aided Manufacturing) software converts your CAD drawings into G-code, which is the programming language that the CNC control software understands.

- The CNC control software (which is the controller of the machine)then reads the G-code and turns it into motion to drive your machine.

Software We Suggest (CAD/CAM all in one)

- Vectric Aspire

- Autodesk Fusion 360

- Mozaik – Specialized in cabinet & furniture

CAD Software

- Google Sketchup – FREE

- Blender – FREE

- Caligari TrueSpace – FREE

- Wings 3D – FREE

- Moi3D

- Corel CAD

- ArtCam

- SolidWorks

- RhinoCAD

- SolidEdge

- AutoCAD

- TurboCAD

- Alibre

CAM Software