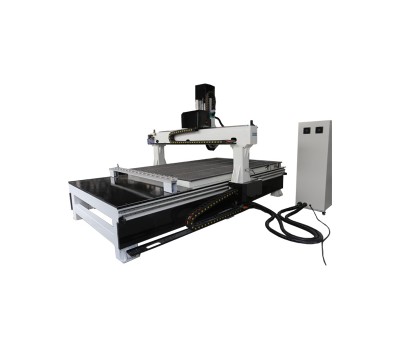

Pro Series ATC CNC Router (Pro Series MK1: Linear Tool Magazine)

The future of production equipment is here.

As our most popular CNC router, the PRO Series offers amazing upgrades in technology, durability, and force. Built to outperform every comparably priced machine on the market, the PRO Series is loaded with top-of-the-line components and technology you’d expect to find in machines that cost $80,000 or more. Add in our free lifetime technical, you simply won’t find a machine that provides more value.

The PRO Series CNC router features over-sized heavy duty structural tube steel frame, gantry, and structural tube steel gantry uprights along with an industrial helical rack & pinion Gear drive system on XY axis, Gear ball screw drive system on Z axis. Designed to produce high quality parts every time whether you are performing nested based sheet work, MDF Doors, one-off custom machining, or anything in between, the PRO Series gives you everything you need for true production. Perfect for manufacturing, furniture, cabinets, signs, R&D, and even at-home use, the PRO Series has the capabilities to take your production to the next level.

Contact us today to learn more about the AlphaCNC PRO Series CNC routers.

Uses & Applications

The Test Test Test has unlimited uses and applications, including:

- Prototype manufacturing

- Nested-based manufacturing

- Sign making

- Engineering

- R&D/Job shops

- Cabinet/door/closet manufacturing

- Musical instrument manufacturing

- Medium duty to high production

- Solid Surface work

- Non-Ferrous material processing

Materials Cut

Can accurately cut virtually any hard material including:

- Wood

- Acrylic

- Plastic

- Foam

- Aluminum

- Brass

- and More

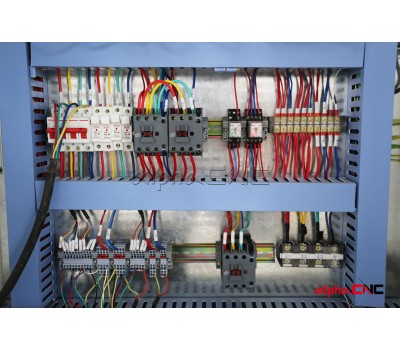

- CE Standard

- Structure: Heavy duty

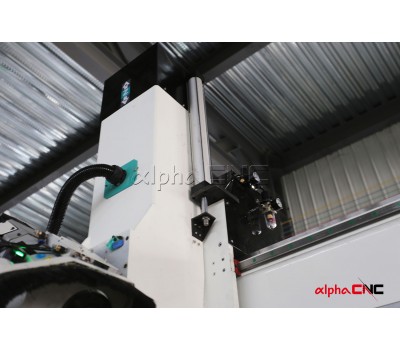

- Spindle: 9kw ATC air cooling spindle

- Spindle rotate 180 degree

- Harmonic reducer on C axis

- Tool magazine: 8-tool in linear

- Control system: Taiwan Syntec 6MB

- Driving motor: Japan Yaskawa servo motor 850w

- Japan Shimpo Gear Reducer

- Inverter: Delta

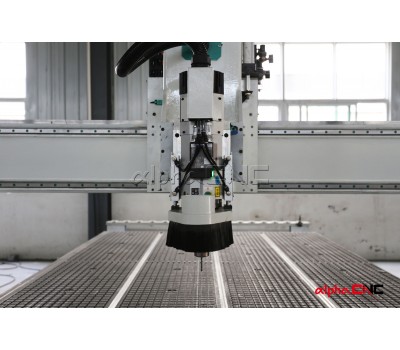

- Table: Vacuum table 6 zone + T-slot

- Vacuum pump: 7.5kw dry rotary van type

- XY axis German Helical rack and pinion gear

- Z axis TBI ballscrew

- XYZ axis Taiwan Hiwin or TBI liner rail 30mm

- Automatic lubrication system

- Vacuum cleaner 2 bags

- Foot switch

- Fiber

- Tool sensor

- Position cylinder

- Vertic Aspire or AlphaCAM

- Machine working voltage: custom made

| APS-1325 | APS-1530 | APS-2040 | |

|---|---|---|---|

| Footprint | 2250*3300*1900mm | 2450*3800*1900mm | 2950*4800*1900mm |

| Cut Area | 1300*2500*400mm | 1500*3000*400mm | 2000*4000*400mm |

| Z Clearance | 200mm standard | 200mm standard | 200mm standard |

| Z Travel | 300mm | 300mm | 300mm |

| Rapid Speed | 35 m/s | 35 m/s | 35 m/s |

| Repeatability | 0.05mm | 0.05mm | 0.05mm |

| Drive Motors | Japan Yaskawa servo motor and driver | Japan Yaskawa servo motor and driver | Japan Yaskawa servo motor and driver |

| Control System | Taiwan Syntec 6MB | Taiwan Syntec 6MB | Taiwan Syntec 6MB |

| Spindle | 9kw ATC air cooling spindle | 9kw ATC air cooling spindle | 9kw ATC air cooling spindle |

| Tool Magazine | 10 Slots Rack Tool Magazine | 10 Slots Rack Tool Magazine | 10 Slots Rack Tool Magazine |

| Running Environment | Temperature: 0℃~45℃ Relative Humidity: 30%~75% | Temperature: 0℃~45℃ Relative Humidity: 30%~75% | Temperature: 0℃~45℃ Relative Humidity: 30%~75% |

Standard Available options

Available attachments for Alpha CNC router models. Please note that some options may not be available on all models or with other options. Some options may result in limiting the cutting/working areas. Contact us for more details

- Drilling Bank

- Oil mist Coolant System

- HSD Aggregate Tool

- Rotary Axis

- Siemens 808D Control System + Siemens 1kw Servo Motor

- Syntec 6mb Control System

- Delta 750w Servo Motor

- Yaskawa 850w Servo Motor

So, what software is involved in CNC? There are primarily three parts:

- Your CAD (Computer Aided Design) software is where you design your parts to be routed, lathed, milled, or cut.

- CAM (Computer Aided Manufacturing) software converts your CAD drawings into G-code, which is the programming language that the CNC control software understands.

- The CNC control software (which is the controller of the machine)then reads the G-code and turns it into motion to drive your machine.

Software We Suggest (CAD/CAM all in one)

- Vectric Aspire

- Autodesk Fusion 360

- Mozaik – Specialized in cabinet & furniture

CAD Software

- Google Sketchup – FREE

- Blender – FREE

- Caligari TrueSpace – FREE

- Wings 3D – FREE

- Moi3D

- Corel CAD

- ArtCam

- SolidWorks

- RhinoCAD

- SolidEdge

- AutoCAD

- TurboCAD

- Alibre

CAM Software