New design APS CNC Router

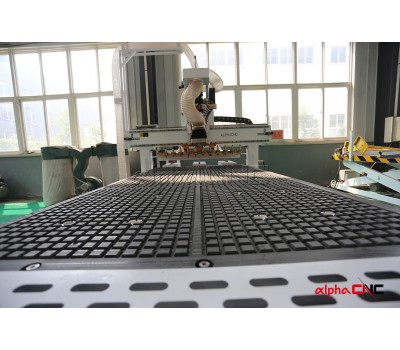

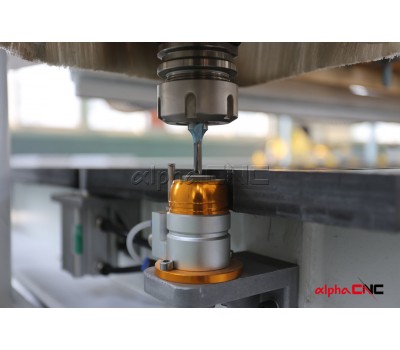

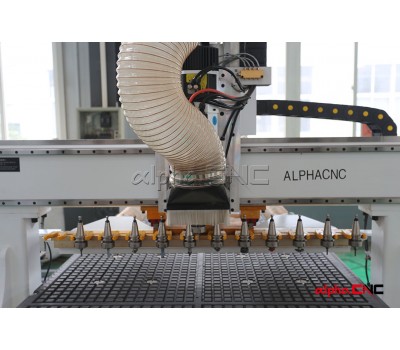

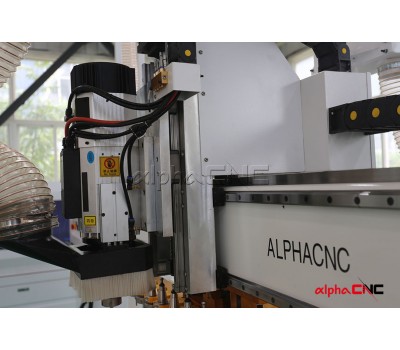

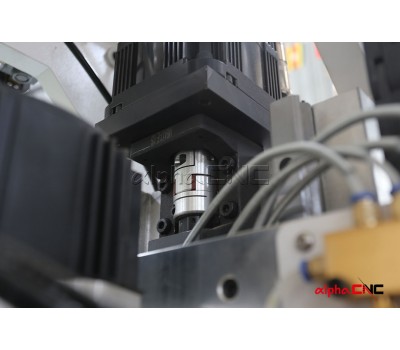

Alpha APS CNC Router is manufactured using global state-of-the-art techniques with advanced engineering, workmanship and built to last with all steel construction and superior components such as precision linear bearings and rails. Key features are a 9KW(12HP) high frequency automatic tool changer spindle with 8-position tool rack, pneumatically retractable vacuum hood and multi-zone vacuum t-slot table. The system includes Servo motors and controls with a Taiwan industrial LNC controller.

The main advantage of the machine is the tool rack moving together with the machine gantry, which will save the tool change time.

The machine can cut about 50 pcs of wood board per 8 hour.

It can process wood, MDF, chipboard, plywood. It is widely used in the cabinet making industry. And it also can process acrylic, plastic, soft metal and many other different materials.

| Parameters | Standard Specifications APS-1325 |

|---|---|

| X,Y,Z Working Area | 1300*2500*300mm |

| Spindle Power | 9kw ATC air cooling spindle |

| X,Y,Z Traveling Positioning Accuracy | ±0.02/2000mm |

| Table Surface | Vacuum and T-slot |

| X,Y,Z Rail and Transmission | X Y axis helical gear transmission, Z axis Taiwan TBI Ball Screw |

| Max. Rapid Travel Rate | 60m/min |

| Max. Working Speed | 40m/min |

| Spindle Speed | 0-24000RPM |

| Drive Motors | Leadshine servo motor and driver |

| Working Voltage | AC380V/3PH/50Hz(option:220V) |

| Command Language | G Code |

| Operating System | Taiwan LNC |

| Interface | USB |

| Software capabilities | Option: Vectric Aspire, Type3, Ucancam, Artcam, Solidworks, etc. |

| Running Environment | Temperature: 0℃~45℃ Relative Humidity: 30%~75% |