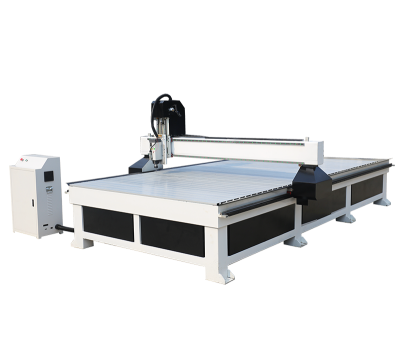

Basic Series CNC Router

An tntry level router for the bold

If you’re looking for an entry level priced CNC router, then your search is over. The AlphaCNC Basic Series is built with the entry level budget in mind, but it comes with a lot more than you’d expect to find on an entry level machine. The AlphaCNC Basic Series gives users the ability to buy a truly solid machine at a price that is affordable for small business owner. With the rack and pinion X & Y Axis, this machine is ideal for hobby and low production shops.

With heavyweight steel construction and heavy duty motors, The AlphaCNC Basic Series gives you the durability and reliability you won’t find in other cheap machines. There simply is no comparable entry level CNC router on the market. Thanks to AlphaCNC Basic Series, you can finally purchase a machine that will take your ideas to the next level or help you realize your business dreams. Contact us today to learn how the AlphaCNC Basic Series can meet your needs.

Uses & Applications

Basic Series has unlimited uses and applications, including:

- Prototype manufacturing

- Nested-based manufacturing

- Sign making

- Engineering

- R&D/Job shops

- Cabinet/door/closet manufacturing

- Musical instrument manufacturing

- Medium duty to high production

- Solid Surface work

- Non-Ferrous material processing

Materials Cut

Basic Series can accurately cut virtually any hard material including:

- Wood

- Acrylic

- Plastic

- Foam

- Aluminum

- Brass

- and More

- Welded steel construction with Stress Relieved Technology

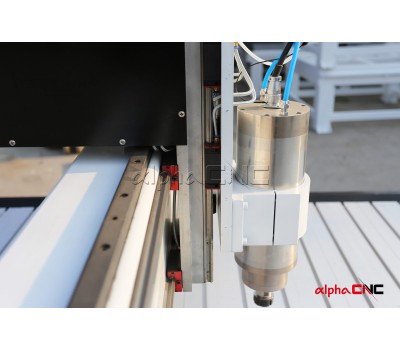

- Steel Tube Gantry (Most Rigid in Class)

- Heavy duty motors (Most Industrial in class)

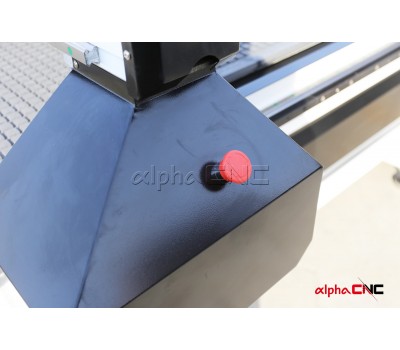

- Auto Tool Zero Sensor

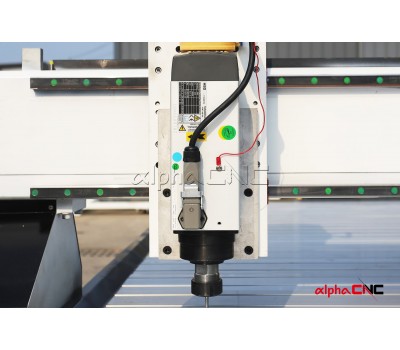

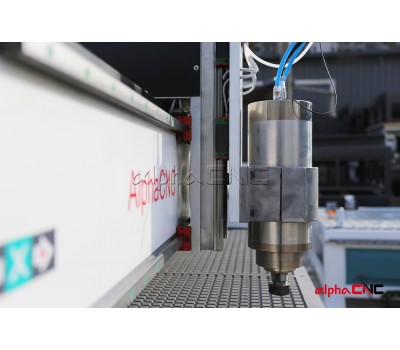

- 3.2kw Liquid-Coolant Spindle

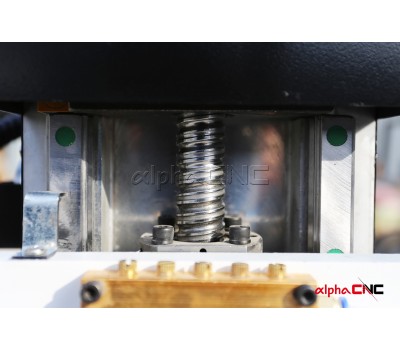

- Component All Mill By Milling Center

- No assembly required – No Bolt Together Designs

- Custom options available to meet your exact needs

- Free lifetime tech support

| ABS-1325 | ABS-1530 | ABS-2040 | |

|---|---|---|---|

| Footprint | 2250*3300*1900mm | 2450*3800*1900mm | 2950*4800*1900mm |

| Cut Area | 1300*2500*150mm | 1500*3000*150mm | 2000*4000*150mm |

| Z Clearance | 150mm standard | 150mm standard | 150mm standard |

| Rapid Speed | 50 m/s | 50 m/s | 50 m/s |

| Repeatability | 0.05mm | 0.05mm | 0.05mm |

| Drive Motors | Leadshine Nema 34 Stepper Motor System | Leadshine Nema 34 Stepper Motor System | Leadshine Nema 34 Stepper Motor System |

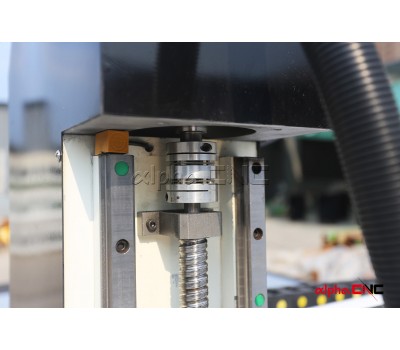

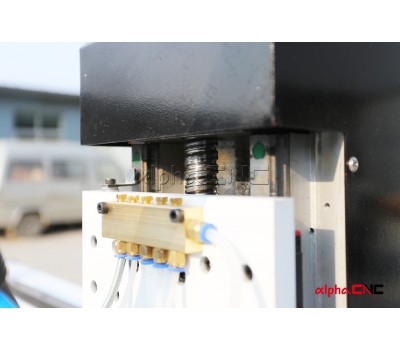

| Drive System | Ball Screw Z axis, Rack And Pinion Gear on X & Dual Y Axis | Ball Screw Z axis, Rack And Pinion Gear on X & Dual Y Axis | Ball Screw Z axis, Rack And Pinion Gear on X & Dual Y Axis |

| Spindle | 3.2kw Liquid-Coolant Spindle | 3.2kw Liquid-Coolant Spindle | 3.2kw Liquid-Coolant Spindle |

Standard Available options

Available attachments for Alpha CNC router models. Please note that some options may not be available on all models or with other options. Some options may result in limiting the cutting/working areas. Contact us for more details

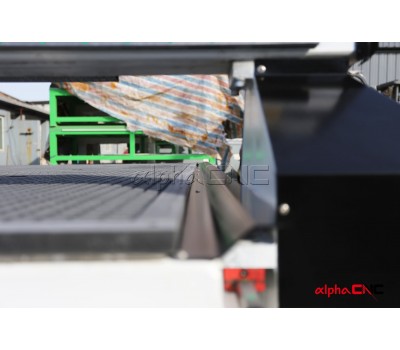

- Hybrid T-Slot/Vacuum Table Top (Included Dry Rotary Vane Vacuum Pump)

- Table Reference Pins (Pop-Up Pins) for Sheet Alignment – Availability dependent on Machine Model

- Rotary Axis

- Dust Collector Options

- 3D Laser Scanner Attachment for Quick 3D Copying (Ask for Details/Availability)

So, what software is involved in CNC? There are primarily three parts:

- Your CAD (Computer Aided Design) software is where you design your parts to be routed, lathed, milled, or cut.

- CAM (Computer Aided Manufacturing) software converts your CAD drawings into G-code, which is the programming language that the CNC control software understands.

- The CNC control software (which is the controller of the machine)then reads the G-code and turns it into motion to drive your machine.

Software We Suggest (CAD/CAM all in one)

- Vectric Aspire

- Autodesk Fusion 360

- Mozaik – Specialized in cabinet & furniture

CAD Software

- Google Sketchup – FREE

- Blender – FREE

- Caligari TrueSpace – FREE

- Wings 3D – FREE

- Moi3D

- Corel CAD

- ArtCam

- SolidWorks

- RhinoCAD

- SolidEdge

- AutoCAD

- TurboCAD

- Alibre

CAM Software